As loading docks become more and more essential to the operation of a business, it is important to consider which type of dock equipment is the best fit for your needs. Dock levelers and dock ramps are two commonly used pieces of equipment, but which one is better? In this blog, we’ll explore the advantages and disadvantages of each so that you can make an informed decision about what’s best for your business.

What Is The Difference Between Dock Ramp And Dock Leveler?

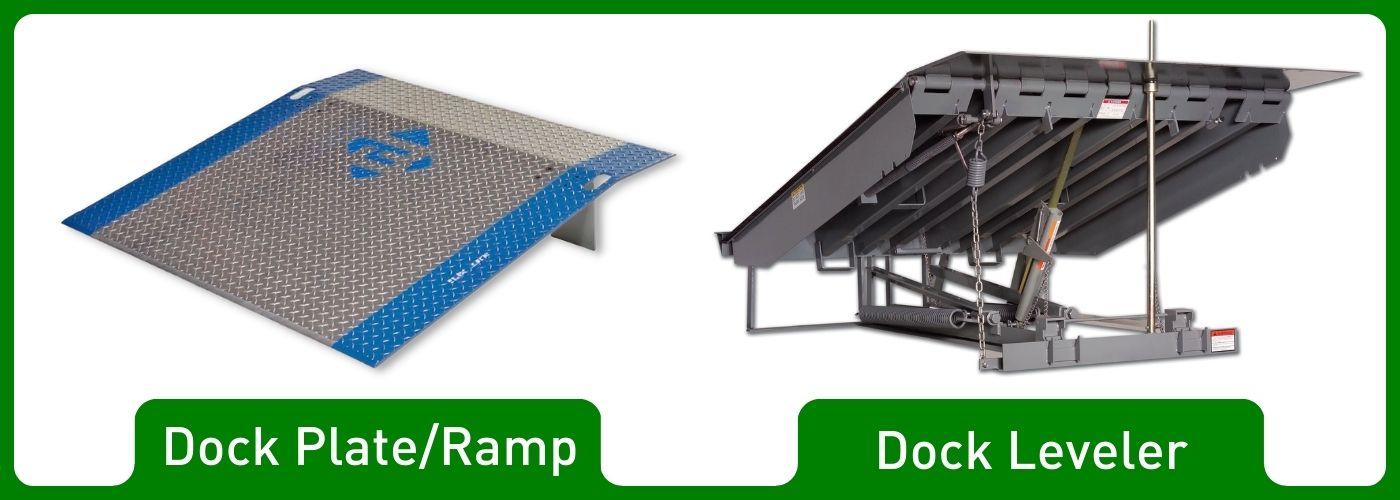

Dock ramps and dock levelers are two different types of loading equipment used in the logistics industry to facilitate the movement of goods between trucks and warehouses. While both are essential for efficient warehouse operations, they differ in terms of purpose, design, and functionality.

A dock ramp is a movable platform that connects the warehouse floor with a truck bed to enable easy loading and unloading of goods. It is typically made of steel or aluminum and can be adjusted to suit the height of different trucks. Dock ramps can be used on uneven surfaces, making them ideal for outdoor loading bays where trucks may have to park at an angle due to space constraints.

On the other hand, a dock leveler is a stationary device that bridges the gap between a truck bed and warehouse floor while ensuring smooth transition during loading or unloading operations. There are many types of dock levelers, but generally, these are operated manually. Dock levelers are located outside the loading dock area and welded onto the building itself.

What Are The Pros & Cons Of A Dock Leveler?

Dock levelers are indispensable tools for loading and unloading goods from trucks. They bridge the gap between the dock and the trailer, allowing workers to move cargo safely and efficiently. However, like any other piece of equipment, dock levelers have their pros and cons that should be considered before making a decision.

One of the main advantages of a dock leveler is its flexibility. They can accommodate a wide range of vehicles with different heights and weights, making them ideal for facilities that handle various types of shipments.

Additionally, they provide a smooth transition from the warehouse floor to the truck bed, reducing the risk of accidents such as tripping or falling when carrying heavy loads.

Another benefit is increased productivity. Dock levelers speed up loading and unloading times by providing a stable platform for workers to operate on. This means more efficient use of time while ensuring safety remains paramount in operations within your facility.

On the other hand, dock levelers can require a lot of maintenance if used heavily. So, if your back-of-house is constantly shipping and receiving goods then it can play a factor into its lifespan.

Not to mention, dock levelers can be costly to install. However, dock levelers can be last for many years if maintained correctly! This is why picking the right dock leveler can help you save money in the long run.

What Are The Pros & Cons Of A Dock Ramp?

While dock ramps are an essential part of many businesses that deal with shipping and receiving goods, they do come with both advantages and disadvantages.

One of the most significant pros of a dock ramp is its ability to increase efficiency in loading and unloading cargo. The ramp allows for easy access to trucks from the dock, reducing wait times and improving productivity. Making it the perfect piece of loading dock equipment.

Additionally, dock ramps can be adjustable in height, making them suitable for different types of vehicles. This versatility makes it easier for businesses to handle various sizes of trucks efficiently.

However, there are also cons associated with using a dock ramp. One major disadvantage is safety concerns. If not used correctly or maintained appropriately, accidents such as falls or equipment damage can occur. They are often made with heavy steel or aluminum, so lifting and placing the dock ramp can cause injuries if not handled correctly.

Lastly, dock ramps are often small, so space is typically tight when maneuvering on them.

How Long Does A Dock Ramp & Leveler Last?

A dock leveler’s typical lifespan ranges from 5-10 years, depending on how often it is used. If the leveler is subjected to heavy usage or harsh conditions such as extreme temperatures or corrosive environments, that could cause wear and tear faster than normal rates.

Proper maintenance can help extend the life of your dock leveler by regularly lubricating its moving parts, replacing damaged components promptly and keeping it clean.

On the other hand, dock ramps usually last longer than their counterparts. These pieces of loading dock equipment can last anywhere from 5-20 years. Dock ramps are typically much more cheaper than a dock leveler since they’re not made from the same high-grade materials as dock levelers.