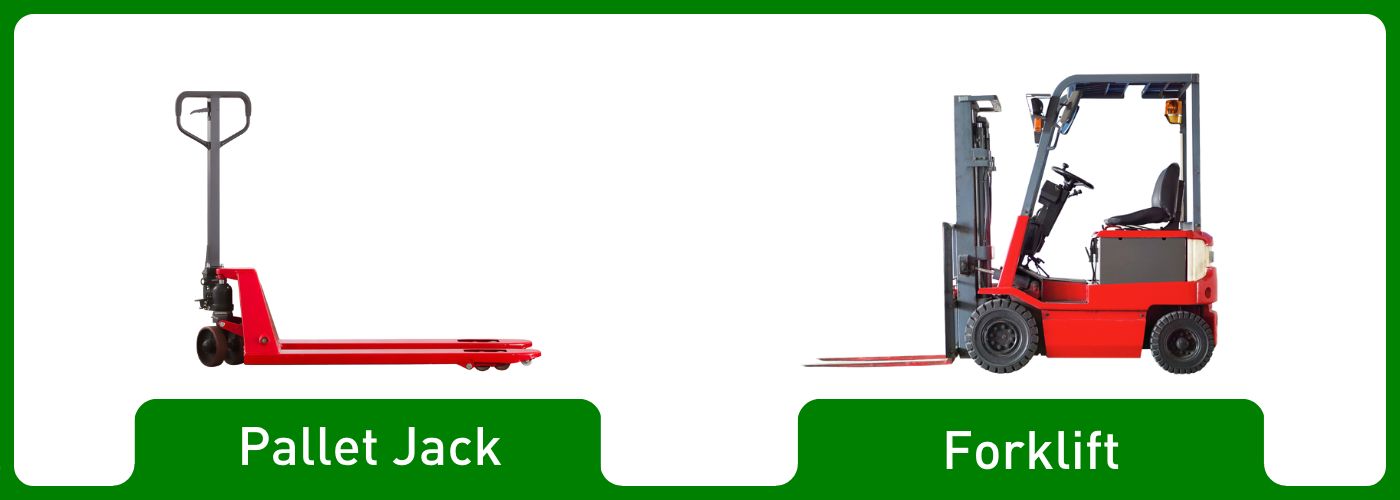

At first glance, one may think that a forklift and a pallet jack are the same due to their similar use in warehouses, factories, and other industrial settings. However, upon closer inspection, there are differences between the two pieces of equipment.

Both are essential for efficiently moving heavy goods, but understanding the different features of each machine is important when considering which one to choose for the job.

What Is The Difference Between A Pallet Jack And A Forklift?

Regarding moving heavy loads in a warehouse, two tools often come to mind the pallet jack and the forklift. While they might seem similar at first glance, there are several key differences between these two pieces of equipment.

Firstly, pallet jacks are designed for simpler tasks like moving pallets short distances within a warehouse. They typically have a smaller size and lifting capacity than forklifts. On the other hand, forklifts have much larger capacities and can move heavier loads over longer distances.

Another important difference is how each tool operates. Pallet jacks are manually operated and require an operator to push or pull them along the ground while steering with a handlebar. Forklifts, on the other hand, feature a motorized engine that allows them to lift loads vertically and move horizontally with ease.

What Is The Disadvantage Of A Pallet Jack?

A pallet jack is an essential piece of equipment in many warehouses and distribution centers. It is a tool that allows workers to move heavy loads around easily, thus increasing efficiency and productivity levels. However, as useful as pallet jacks can be, they also have disadvantages.

One of the main drawbacks of using a pallet jack is that it can only handle a limited amount of weight. Depending on the type of pallet jack used, most models have a maximum weight capacity ranging from 2,000 to 5,000 pounds. If you need to move heavier loads, you may invest in more powerful equipment, such as forklifts or other lifting devices.

Another disadvantage of using a pallet jack is that it requires manual labor.

What Is The Disadvantage Of A Forklift?

Forklifts are commonly used in warehouses, construction sites, and other industrial settings to move heavy objects from one place to another. While these machines have made lifting and transporting tasks much easier, they also have some disadvantages that must be considered. One of the primary disadvantages of a forklift is the potential for accidents.

Due to their large size and weight, forklifts can cause serious injuries or even fatalities if not operated properly. The risk of accidents increases when inexperienced operators are behind the wheel or safety protocols are not followed strictly.

Another disadvantage of a forklift is its high cost. Forklifts require significant investment initially, which may not be feasible for small businesses or startups.

Maintenance costs associated with regular repairs and replacements add up over time as well. Finally, using a forklift can create additional expenses related to training and certification requirements.

What’s Better, A Forklift or Pile Jack?

When it comes to material handling, there are a variety of tools and equipment available. Two popular options for moving heavy loads in warehouses and factories are the forklift and pile jack. Both have their advantages and disadvantages, so it’s important to understand which one is better suited for your specific needs.

Forklifts are versatile machines that can lift heavy loads to several tons. They come in various sizes with different lifting capacities so you can choose the right one for your requirements. Forklifts are particularly useful when loading and unloading trucks or containers because they have forks that can extend outwards or upwards, depending on the situation.

On the other hand, pile jacks (also known as pallet jacks) are much simpler machines that serve a specific purpose – moving palletized loads from one place to another.

In conclusion, when deciding between a forklift and a pallet jack, it is important to consider the size of the load being moved, the height from which it needs to be lifted, and how far it needs to travel. Forklifts are better equipped for heavy loads that need to be lifted higher than a pallet jack can manage, whereas a pallet jack is more suitable for lighter loads that need to travel short distances.